What are Pre-Engineered Buildings?

The Concept:

Optimizing Efficiency in Steel Construction

PEBs represent a revolutionary approach to steel buildings, prioritizing both cost-effectiveness and speed. Here's what sets them apart:

- Material Optimization: Through advanced engineering, PEBs utilize a minimal amount of steel while ensuring structural integrity. This translates to lighter yet robust buildings, similar to how structural beams are designed with varying thickness based on load requirements.

- Pre-Fabrication Advantage: All PEB components are meticulously pre-fabricated in controlled factory environments using modern equipment. This streamlines the construction process significantly compared to traditional methods.

- Fast and Efficient Assembly: Upon delivery to the site, the PEBs are quickly erected using a bolt-together system, minimizing on-site construction time and labor costs.

This innovative concept, developed in the 1960s, has transformed the construction industry by offering several key benefits:

- Reduced Construction Costs: Minimized material usage and efficient assembly lead to significant cost savings.

- Expedited Project Completion: Pre-fabricated components and faster assembly ensure a quicker building turnaround.

- Durable Steel Construction: PEBs offer long-lasting strength and resilience.

Overall, PEBs provide a compelling solution for those seeking a cost-effective, time-saving, and structurally sound building solution.

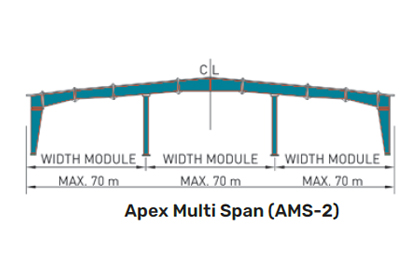

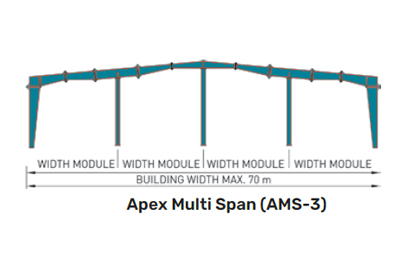

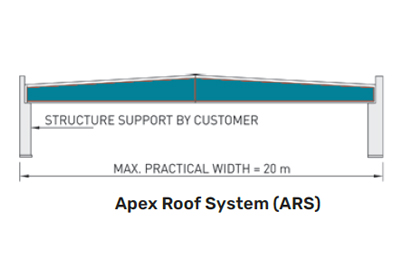

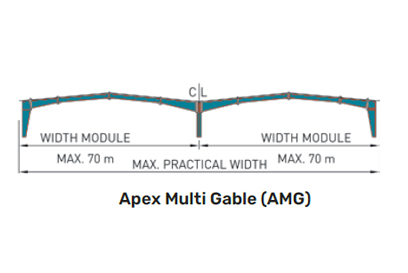

Framing Systems

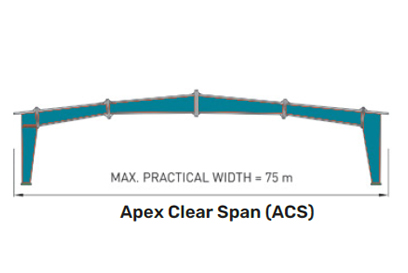

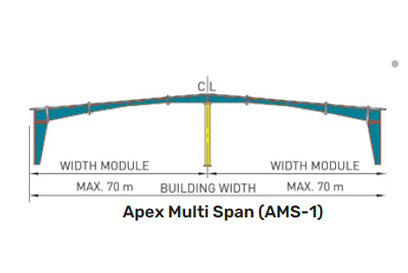

Apex Pre-Engineered Steel Buildings are 100% custom designed to provide maximum space utilisation, excellent strength and highest safety standards.

Our basic architectural measures include:

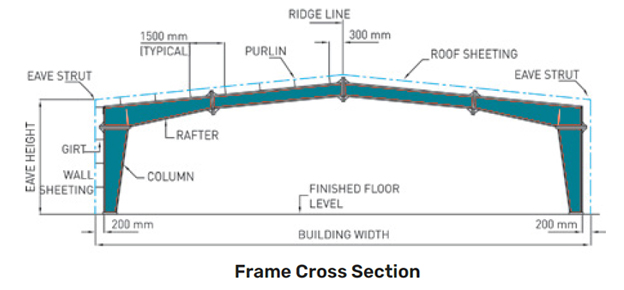

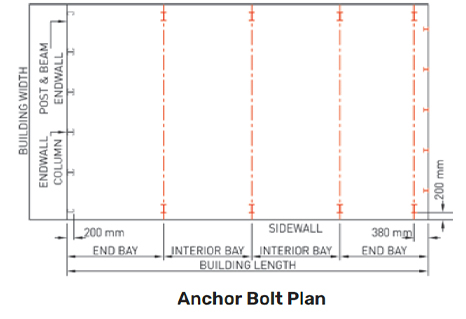

- Building Width: the distance from the outside of the eave strut of one sidewall to the outside of the eave strut of the facing wall.

- Building Length: the distance between the outside flanges of endwall columns in the facing endwall.

- End Bay Length: the distance from the outside of the outer flange of endwall columns to the centre line of the first interior frame columns

- Interior Bay Length: the distance between the centre lines of two adjacent interior main frame columns, which usually range from 6m, 7.5m and 9m to 15m.

The Building Height is the eave height, which is the length from the foot of the main frame column base plate to the top outer point of the eave strut and can measure up to a height of 30m. In the case of columns that are recessed or elevated from the finished floor, the eave height is the distance from the finished floor to the top of the eave strut. The Roof Slope is the angle that the roof forms with respect to the horizontal and is commonly 1/10.

Apex buildings are designed to meet every stringent local and international code - IS (Indian Standard), AISC (American Institute of Steel Construction), AISI (American Iron & Steel Institute), MBMA (Metal Building Manufacturers Association) and AWS (American Welding Society).